Your guide to choose an automatic gate motor

December-2024

Content

1) Introduction

An automatic gate is a quick and easy way to open and close your home or business gate. You can control it via various means such as a remote control, keypad, RFID tag, or even your mobile phone. The biggest advantage to use an automatic gate is convenience: it saves you time and effort in your daily routine. It also increases your property value, enhances privacy, controls access in/out, and makes a great first impression of the entrance of your property!

There are two main types of gates: sliding and swing gates. Sliding gates are perfect for saving space, making them a favorite in Mauritius. They slide along a track, leaving room for landscaping or parking. Swing gates, on the other hand, are ideal for wide or open spaces. They offer a classic look but need plenty of room to swing open, so the area must stay clear. A ‘leaf’ is the term used to describe the part of the gate that moves to open or close.

2) Gate motors

Once you have chosen the type of gate for your property, the next step is to select a gate motor, also called an ‘actuator’ or ‘operator’. There are many brands on the Mauritian market which are imported from Asia, South Africa, or Europe. They all vary in performance and features. In fact, gate automation was invented by the Italians, so they understand it better than anyone else. TropiGuard supplies gate motors from Comunello, which is one of the most respected Italian manufacturers of gate automation.

Here are the main considerations to choose a gate motor:

The dimensions, weight, and frequency of use of your gate

For swing gates, additional parameters to check are the cross-sectional dimensions of the pillar onto which the gate is hung and the position of the hinges

Motor performance in terms of mechanical, electrical, safety and security aspects

Aesthetics or personal design preferences

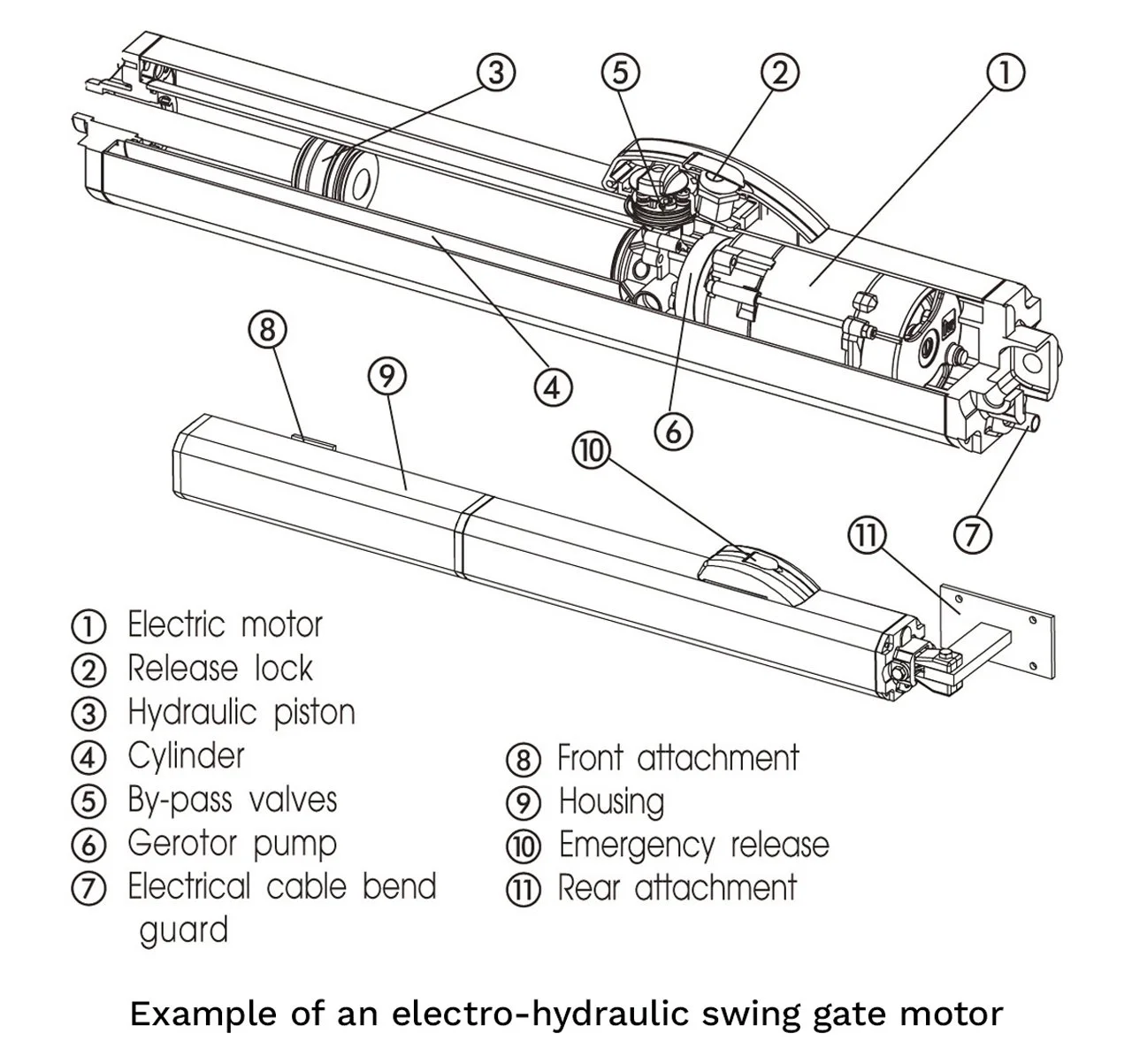

There are two kinds of gate motors: (a) electro-hydraulic and (b) electro-mechanical, each with pros and cons as highlighted below. In this blog, we will focus only on electromechanical motors mainly because it is the type of motor that is best suited for our tropical climate.

a) Electro-hydraulic motor: the motion of the gate is achieved by controlling the flow and pressure of hydraulic oil in the system using an electric motor and pump. These systems are best suited for large and heavy gates with high frequency use. They are durable and can last many years due to the low wear of the internal components. They can also handle extreme cold temperatures well, making them ideal for sub-zero winter conditions in countries like Canada.

However at higher temperatures (e.g. in warm climates) the viscosity of the hydraulic oil changes which affects the overall system performance in both the opening and closing of the gate. That makes electrohydraulic systems unsuitable for Mauritius. There are other drawbacks such as the possibility of oil leaks, oil contamination, and lack of precision in the gate movements during operation. While electrohydraulic motors are reliable in the right conditions, their challenges make them less practical for tropical climates. Note, you can only use these motors on swing gates.

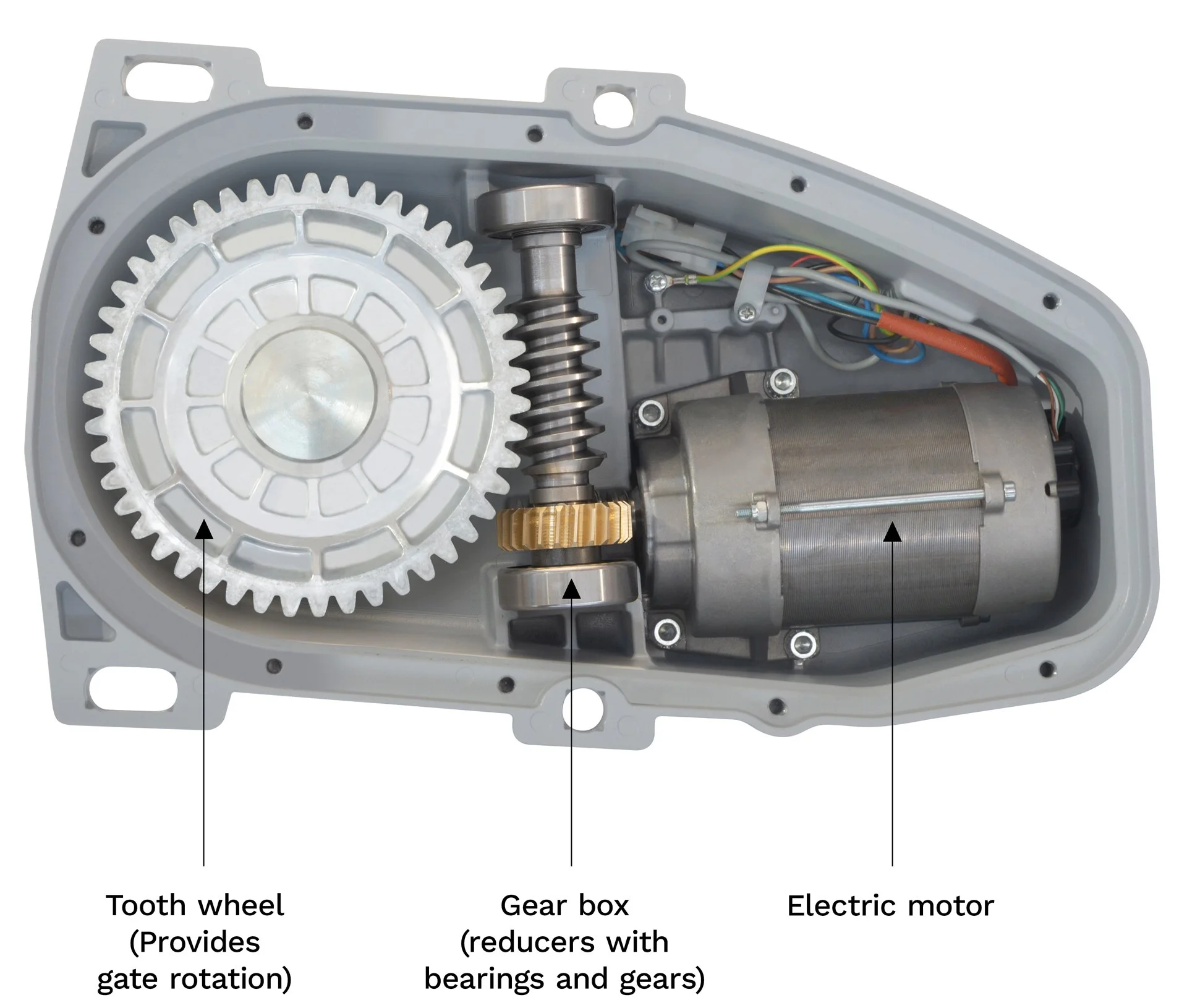

b) Electro-mechanical motor: the motion of the gate is generated mechanically by an electric motor connected to gears. This motor is simple to install and can last many years with regular maintenance, although some internal components may wear down faster with frequent use and under heavy loads. It is also vulnerable to cold temperatures, dust and water. However, newer models are improving to handle heavy loads and frequent usage by using advanced materials, manufacturing precision, and lubrication.

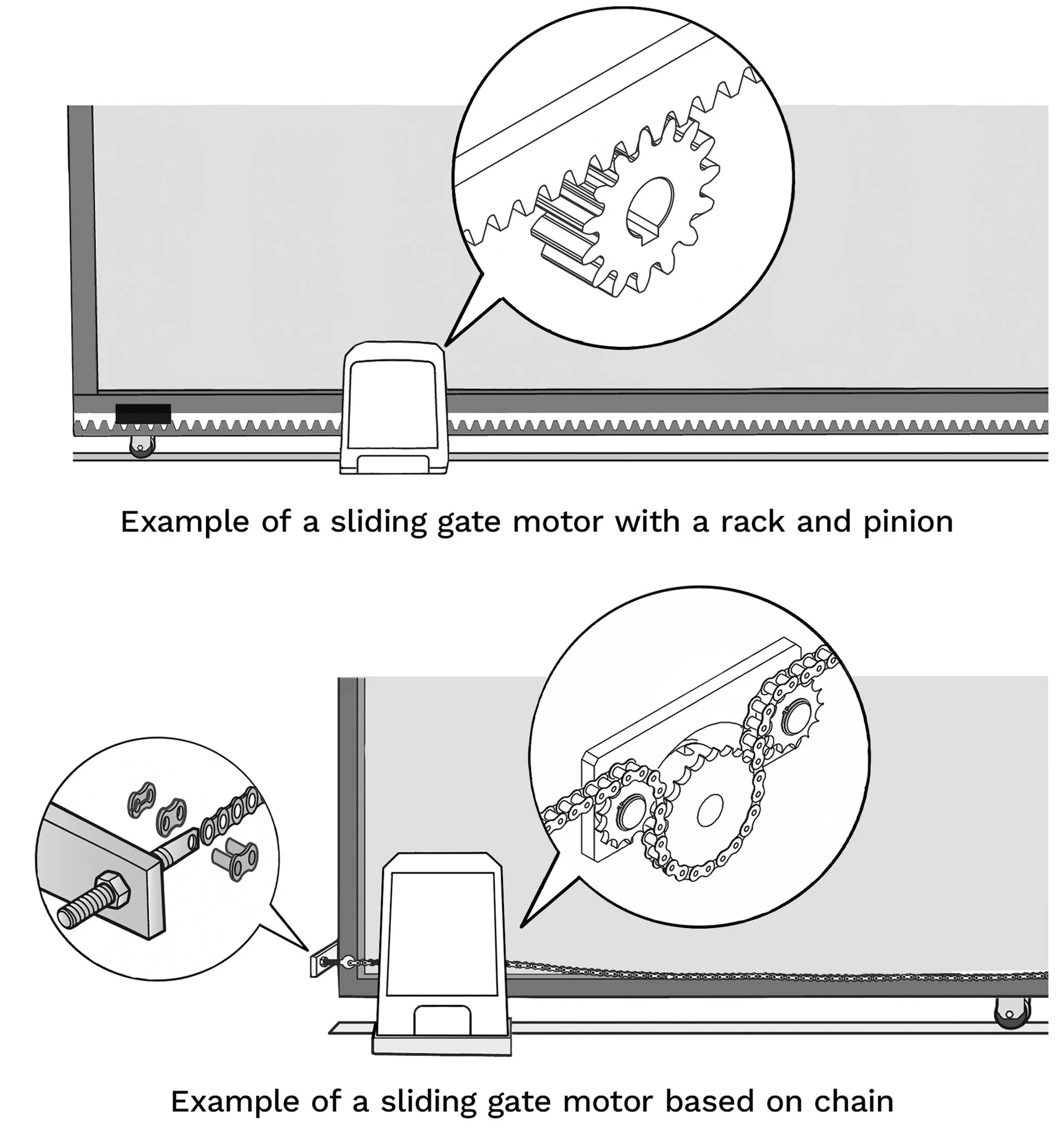

For sliding gates, mechanical movement is generated using a toothed rack and pinion system (which is popular in Europe), or, using chains (which is popular in North America). Chains are better suited for cold weather because the system can handle large debris such as snow. However, the chains provide less precise or controlled movement, create noise during use, and they may leave a grease line on the driveway.

As an example, Comunello FORT sliding gate motor uses a toothed rack and pinion system. The motor assembly consists of only a few components which effectively minimizes the risk of breakdown while being able to operate intensively continuously. The rack material can either be supplied in galvanized steel or nylon. In fact many installers in Mauritius typically offer nylon racks. At TropiGuard, we supply both galvanized steel and nylon racks, giving you the flexibility for your gate project.

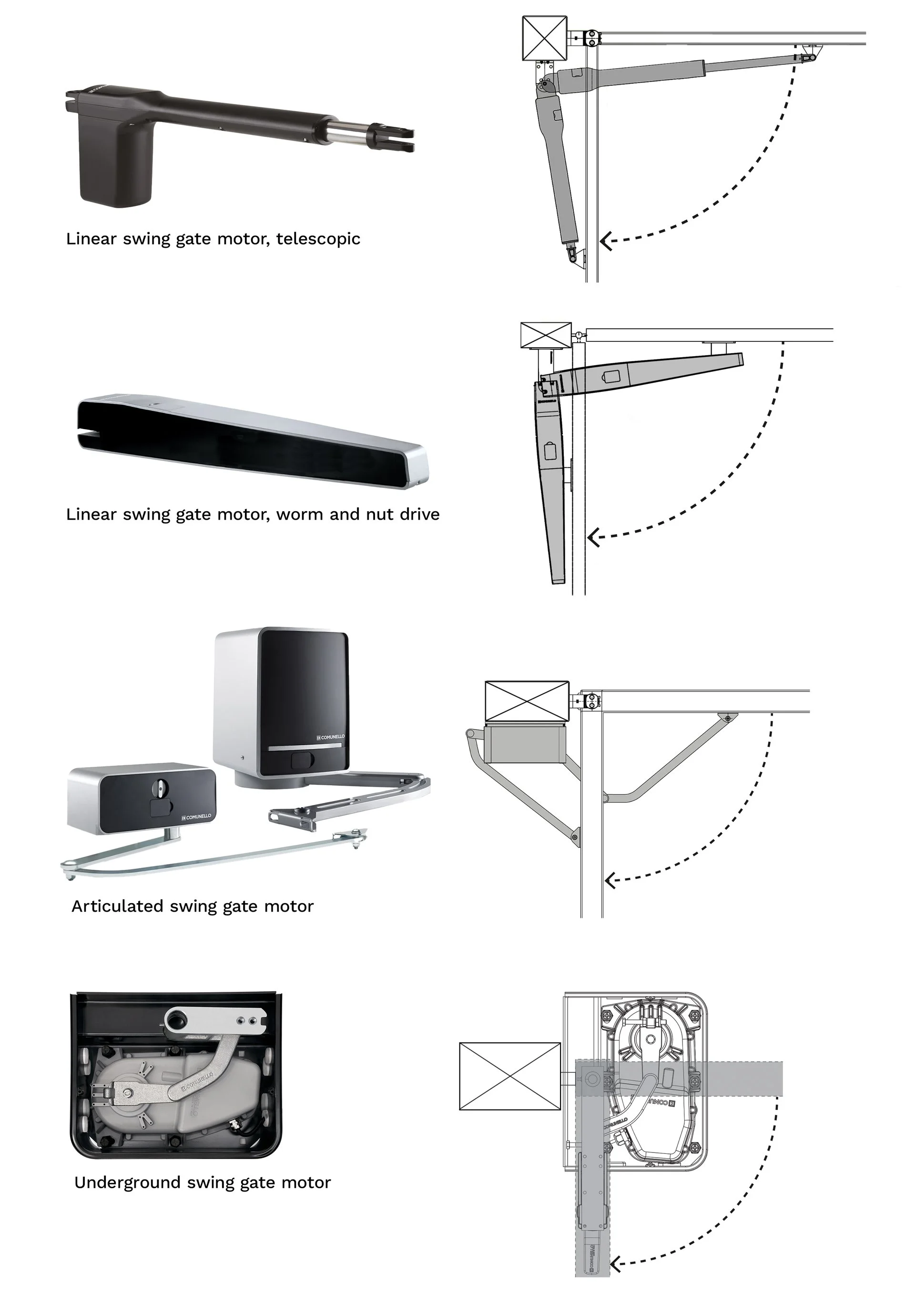

For swing gates, there are three electromechanical motors options: linear, articulated, and underground motors. The choice of these are based on the dimensions of your gate and that of the gate pillar. Depending on which system you choose, you will normally be able to swing your gate open between 90 degrees and 130 degrees in one direction.

The most common type used for swing gate is the linear motor. There are two designs available: one with a telescopic rod, and the other is a worm and nut drive. Both are powered by an electric motor and they have each their own merits. On the practical side, more frequent maintenance can be required for the telescopic rod since it is necessary to keep the telescopic rod clean from dust or dirt, as well as, ensuring there is enough lubrication. Dust and dirt accumulation at the seal can slow down the system and create noise.

Next is the articulated swing gate motor which is the alternative solution if it is not technically possible to install a linear swing gate motor. This happens when the swing gates are hung centrally on wide pillars, e.g. a pillar cross-section of 30 cm x 30 cm which is not uncommon in Mauritius. These systems are generally easy to install and the main drawback is that the articulated arms require space to move (when retracting), to fully open the gate.

Your next option will be an underground swing gate motor. If you prefer to maintain the aesthetics of your gate without having to see the automation equipment, then you will need this type of motor. These systems are buried underground close to the gate pillar, and sealed within their own corrosion-resistant metal container. The motors will provide the required automation just like the other systems above, without being affected by the size of the gate pillar.

Now that you are aware of the various types of gate motors available, let’s address their mechanical, electrical, safety and security aspects - to help you choose a motor that fits your needs.

3) Mechanical performance

a) Load rating

All motors have a maximum load they can handle as defined by the manufacturer (refer to the product datasheets). You should always select a motor that can support more than your gate’s weight, to avoid over-stressing the system. Just like driving a car at its maximum speed every day can wear out the car engine quickly. The same principle applies to both sliding and swing gate motors.

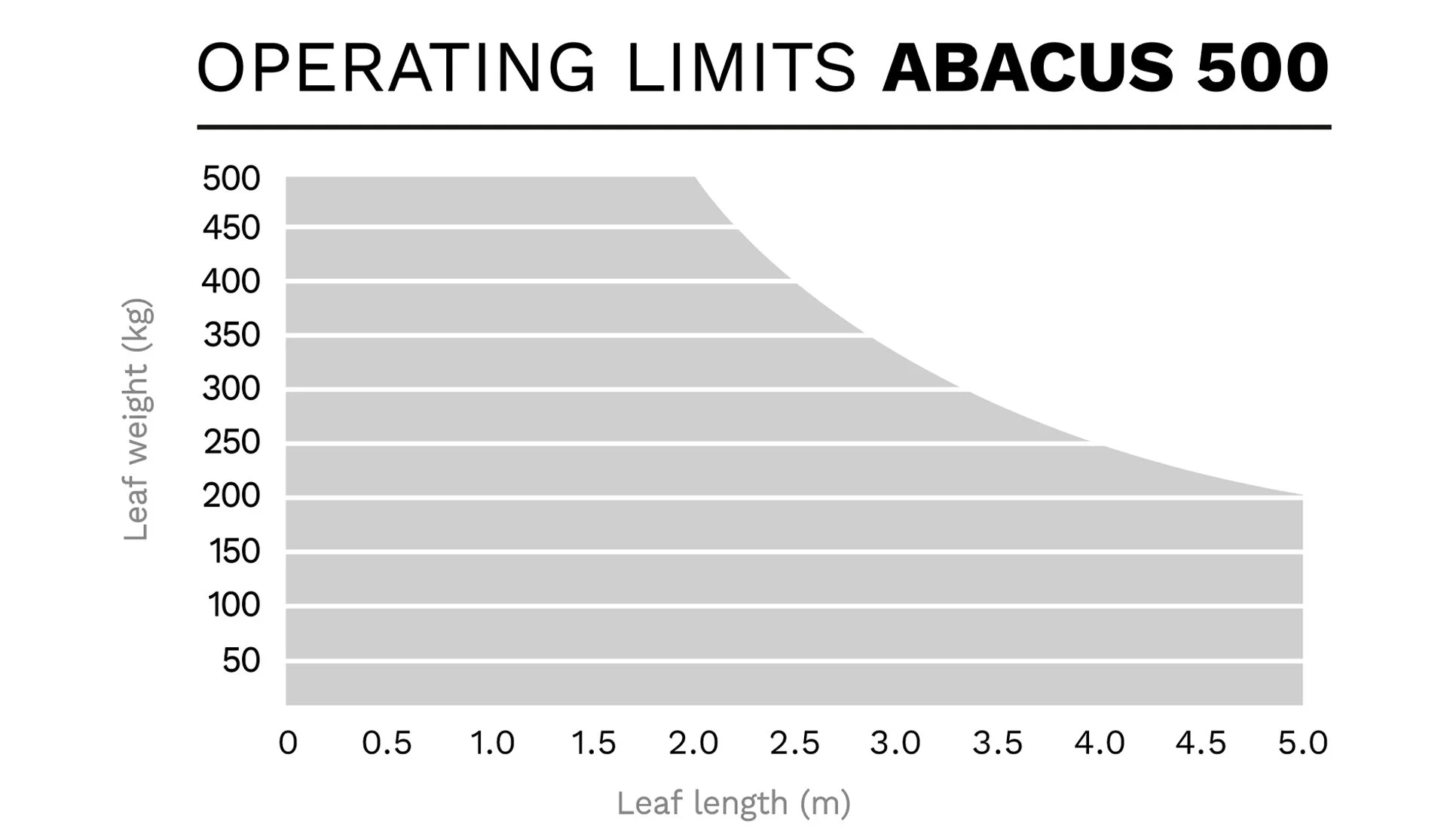

For swing gates, an additional parameter to be considered is the length of the gate. Manufacturers often provide charts (refer to the product datasheets) to help with the selection of an appropriate motor when the gate dimensions and weight are known. See example picture from Comunello, showing the operational limit of the Abacus 500 swing gate motor. Any combination of gate’s weight and length within the defined envelope can be handled by this motor.

In practice, there are other loads to be considered such as from wind and friction. As they are not straightforward to calculate or determine, it is recommended to remain well below the load limits as defined by the manufacturer. This ensures your motor is not overloaded and it can therefore operate without loss of performance over time.

b) Duty Cycle

How frequent your gate is opened and closed per day is an essential input in the selection of an appropriate gate motor. For example, a residential gate can be used a few times per day, while an industrial gate can be utilized every 5 to 10 minutes per work day. With each cycle, heat is generated internally by the motor and its internal components tend to wear out under friction.

Manufacturers therefore use the term ‘duty cycle’ to quantify the acceptable frequency of use of the gate motors. The duty cycle refers to the period during which the gate motor can continuously operate before it requires a rest period to avoid damage. This is often expressed as a percentage, or, in terms of operating modes. Electric motors with an ‘S1’ rating are designed for continuous operation while those with an ‘S2’ rating are meant for short-term use only. Meaning:

A gate motor with an S1 rating have no limitations in the number of opening and closing cycles. The motor can be used 100% of the time and it rests when the vehicle passes through the opening

A gate motor with an S2 rating of 80% will operate for 8 minutes and requires another 2 minutes of rest before re-starting, considering a 10 minutes period

It is critical not to exceed the duty cycle rating of the motor to avoid causing the motor to overheat or to quickly wear out its internal components. At TropiGuard, we use gate motors from Comunello that have an intensive duty cycle (S1 rating) so you can be sure you are able to use your automated gate continuously all day long. Note that Comunello tests all its gate motors and road barriers under various conditions in real size, to guarantee its products have reliable performance and durability.

c) Maximum speed and thrust

The force (or thrust) generated by the motor to move the gate and the speed at which the gate travels are related. Simply put, they are indirectly proportional to each other: as one increases, the other decreases. A good analogy is how your car gears work: in first gear, you get high torque (thrust) and low speed, while in sixth gear, you get lower torque but higher speed.

Both speed and thrust are important in gate automation. A fast-moving gate is convenient, minimizing the time you spend waiting for it to open or close. However, the motor must also apply enough force to overcome friction opposing the movement of the gate. Otherwise the gate would simply not move especially if there are small debris or rocks in its tracks. Over time, the motor can be damaged if it is continuously pushed near its limit. To address this, manufacturers carefully design the gearbox and motor to balance speed and thrust effectively.

As safety is also associated with a moving gate, it is a good practice to limit the speed. In the event the moving gate makes contact with an obstacle, the impact force generated can be large if the speed just before collision is high. This risk is particularly concerning for house pets or small children who may not fully understand the dangers of a moving gate. They can easily get hurt if their presence is not detected by the gate motor. Hence, to prioritize safety, at TropiGuard we follow safety recommendations given in the standards. See below for more details.

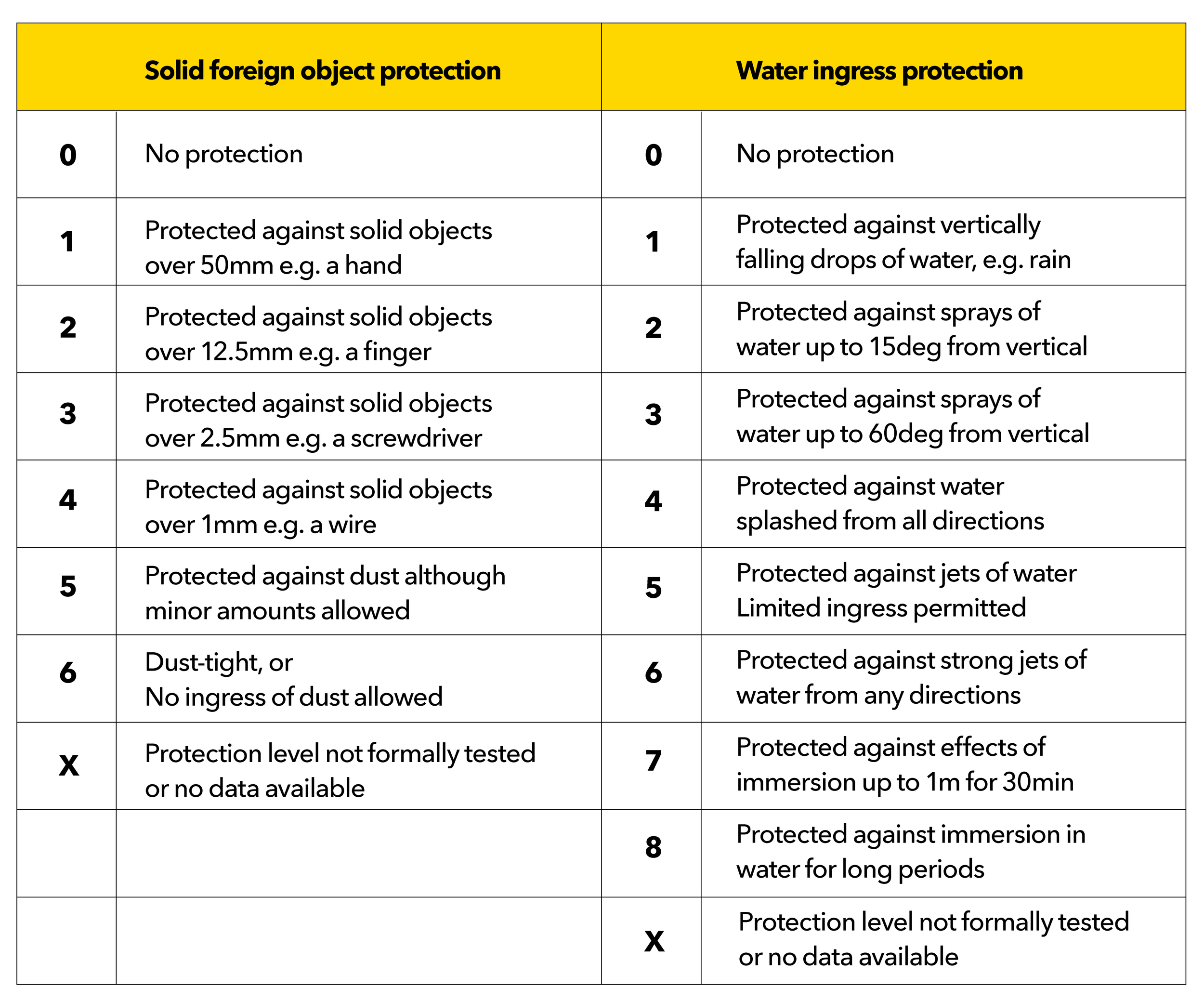

d) IP rating

The Ingress Protection (IP) rating as defined by IEC/EN 60529, is an internationally recognized standard to define an electrical product’s ability to withstand the ingress of liquid and dust. The IP rating uses a 2-digit system to define its protection rating. The first digit represents protection against solids and the second against liquids.

Refer to the table which summarizes the various IP ratings. A gate motor with a high IP rating is then designed in such a way to ensure the system is resistant to dust and water - thereby ensuring durability and reliability under various conditions including heavy rainfall. For instance, Comunello gate motors offer IP44 and IP67 ratings, which are considered high standards. Here is their respective meaning:

IP44: Protection against solid objects over 1 mm (like wires) and water splashes from any direction

IP67: Complete dust protection and protected from immersion in water up to 1 meter, for at least 30 minutes

4) Electrical performance

a) Power consumption

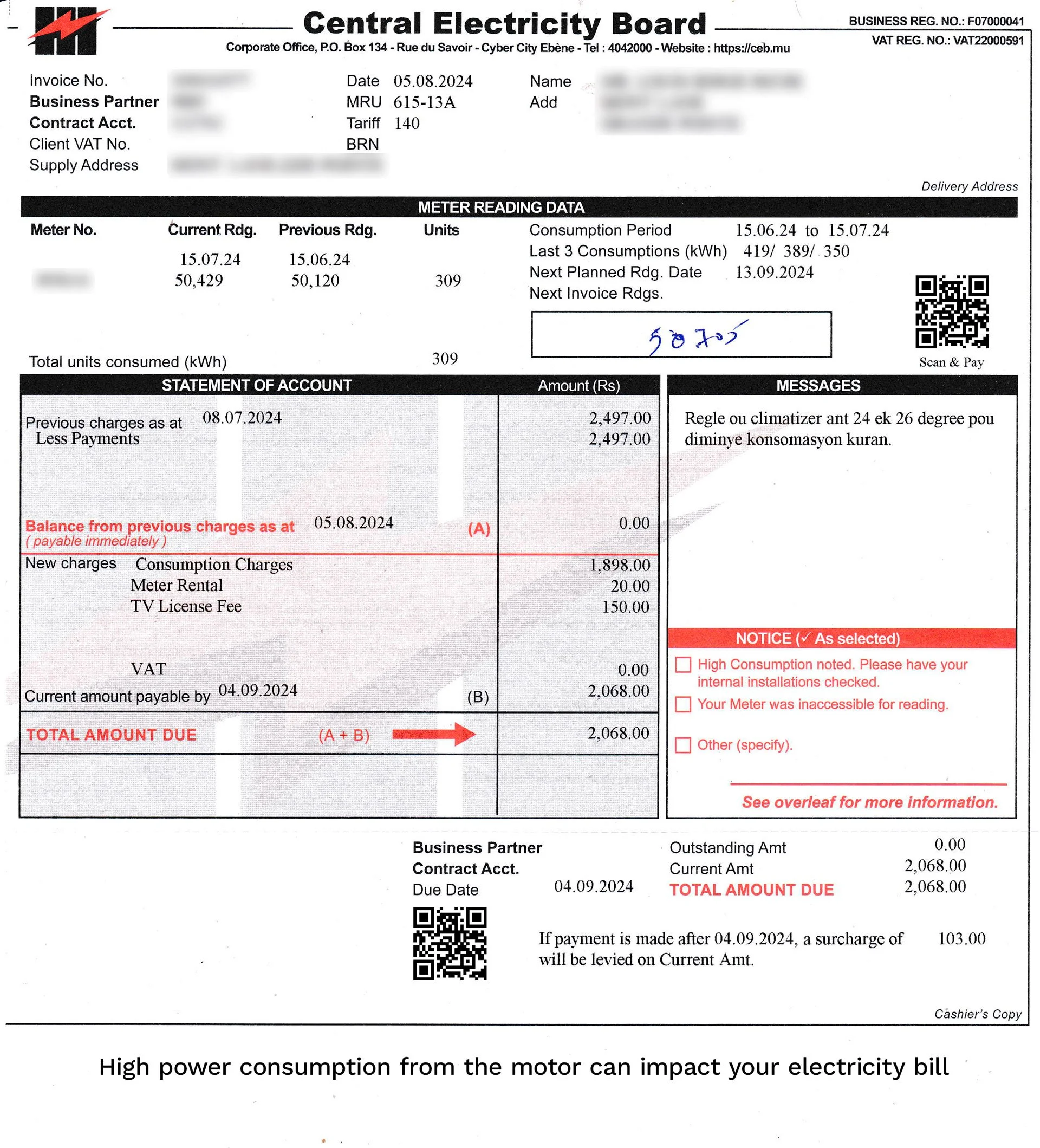

The gate motor uses electricity from your home to operate. Therefore, a key aspect to check is its electrical power consumption which has a direct impact on your electricity bill. In the case of Comunello motors imported by TropiGuard, the AC current is converted into DC current which in turns power the motor. Comunello uses a low voltage 24 Vdc motor to create the desired motion of the gate.

For example, Comunello FORT 400 sliding gate motor consumes 70 watts during operation under the rated load of 400 kg. If you use it for 1 hour per day for 30 days (~1 month), that will be a total of 2.1 kWh. Depending on your electricity tariff and overall monthly consumption from CEB, the cost for using 2.1 kWh is likely small.

At TropiGuard, we prefer using low voltage 24 Vdc motors mainly because:

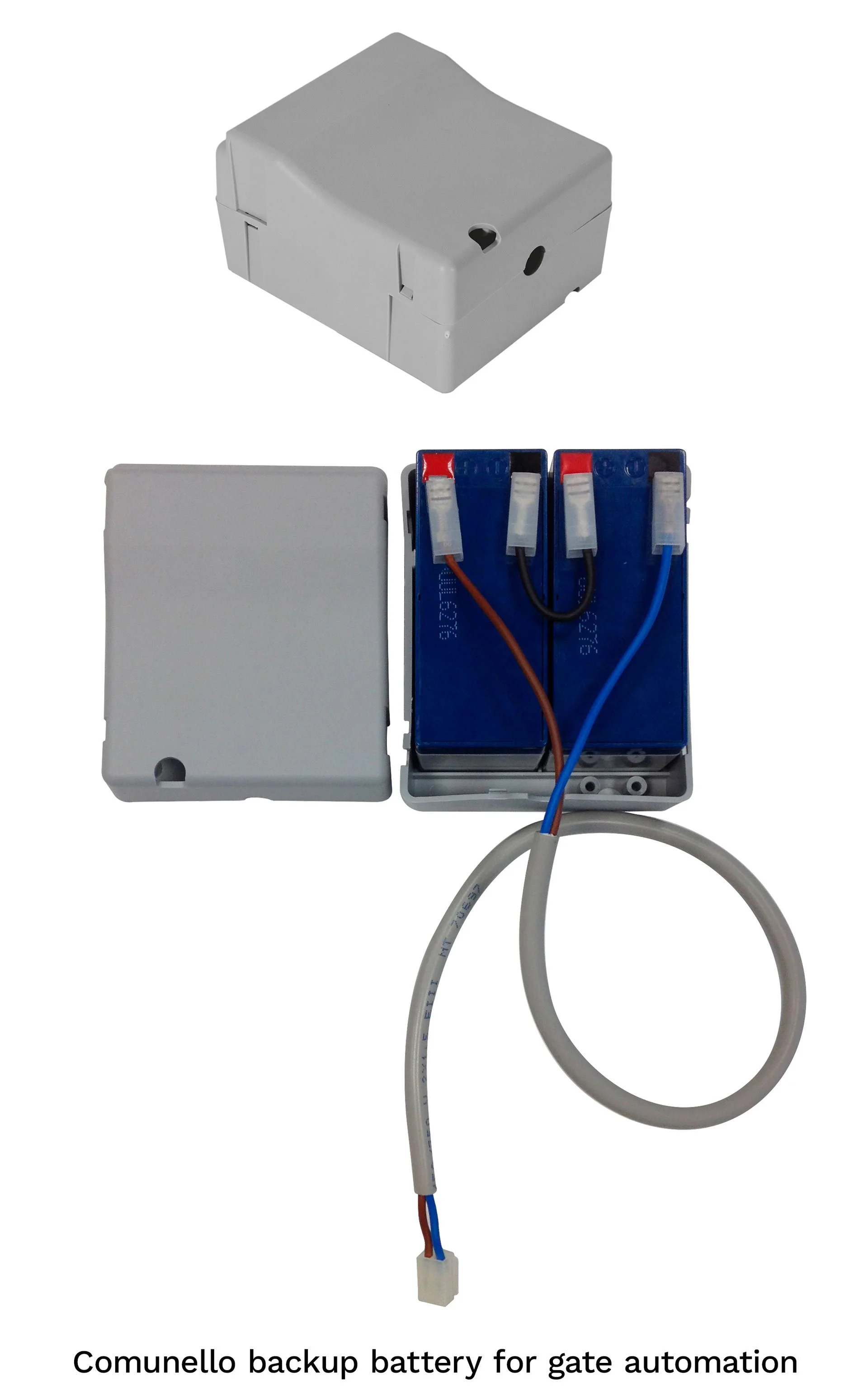

You can add a backup battery which provides emergency power in case of a power outage

DC motors are usually energy efficient and do not get hot quickly, making them a reliable choice for long-term use

DC motors offer precise regulation of speed and torque. Their relatively high torque output than AC motors makes them ideal for handling heavy gates

The controller in the DC motor can read the load on the motor with more accuracy, which means an obstacle can be detected with more precision to enhance safety

b) Backup battery

Most gate motors come with a special release key. This key is used to manually unlock and disengage the motor in case of emergencies or power outages. Once unlocked, you can manually open or close the gate.

Alternatively, if you have a backup battery installed with the system, you will be able to continue using your automatic gate as long as the battery is not depleted. The basic operation of a backup battery for an automatic gate occurs in two stages:

Charging phase: during periods when the gate is not in use and there is electrical energy available, the backup battery is recharged via a dedicated charger integrated in the system

Release phase: depending on the system and in case of a power failure/shortage, the backup battery is activated allowing you to continue using the gate automation

In fact, a well-designed motor will use the least amount of electrical energy from the battery, allowing for more backup cycles until the mains are restored. However, in some situations, the number of backup cycles may decrease if the motor consumes more energy than required due to factors such as frictional resistance of the gate. To prevent complete battery depletion under these conditions, the system permits only a limited number of opening and closing operations. In effect, the battery is intended for use during emergencies only.

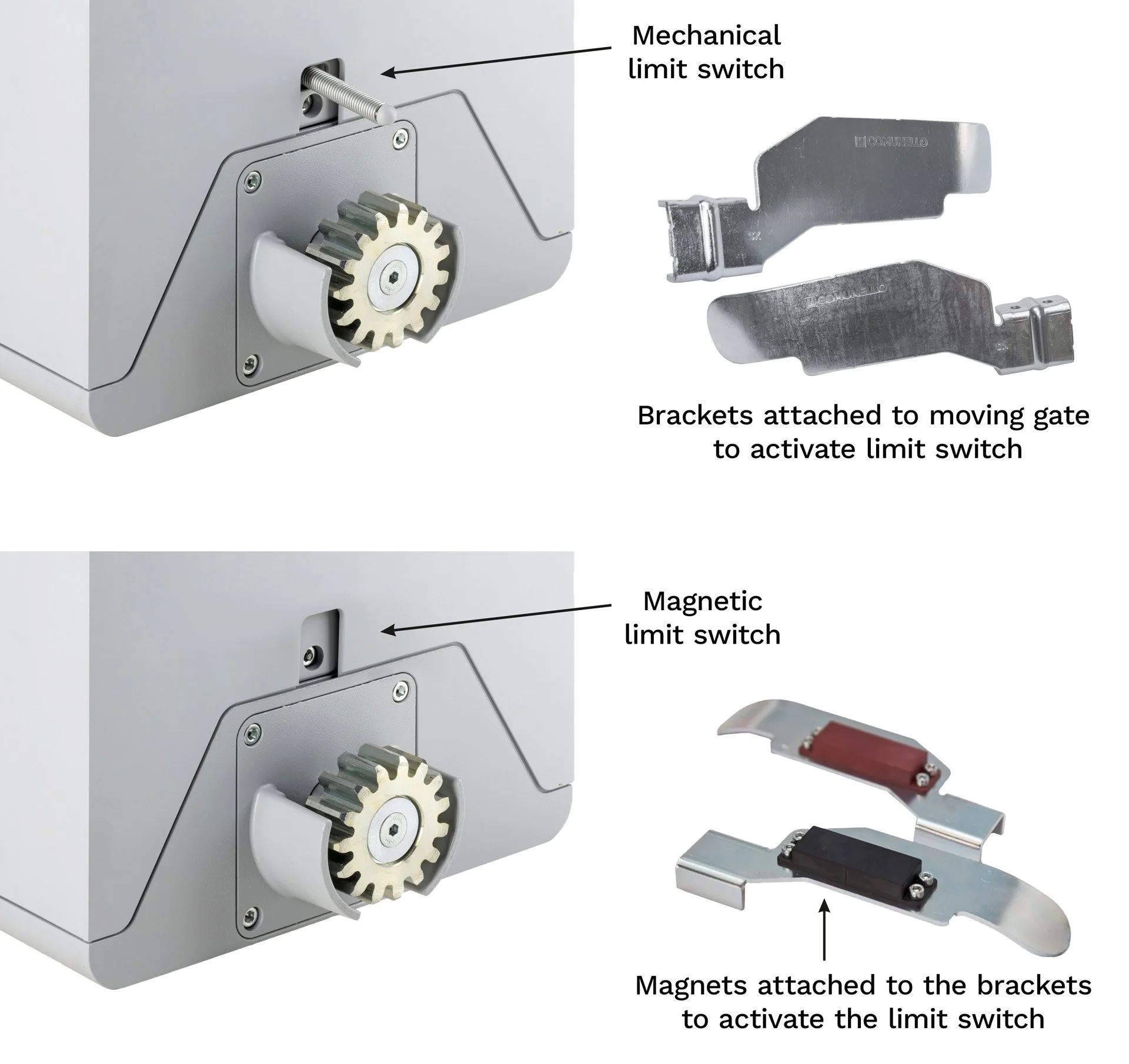

c) Limit switch

The limit switch serves a dual function. Firstly, it ensures the motor stops precisely when it should. When the gate reaches its fully open or closed position, the limit switch activates (via mechanical or magnetic contact) and cuts off power to the motor to effectively preventing the gate from moving further.

Secondly, from an electrical perspective, the limit switch protects the electric motor from drawing excessive current due to an unsafe load. Overcurrent protection is essential because excessive current can cause damage to electrical components on the actuator. Overcurrent occurs when the motor is subjected to more load than it can handle. For example, once the gate reaches its end of stroke on opening or closing, the resistance in movement will prompt the motor to apply more force by drawing maximum current. Another example where overcurrent is triggered is when there is a physical obstruction in the gate’s path.

The good news is that all Comunello sliding and swing gate motors come with a limit switch! They can either be mechanical or magnetic configurations.

5) Safety and security performance

a) Standards

As explained above, gate motors use high levels of force to move gates. Most people underestimate the power of these systems and do not necessarily realize the potential hazards associated with an incorrectly designed or installed system. There are regulations in Europe governing the design, installation, and maintenance of automatic gates, garage doors, and road barriers to ensure the safety of users and prevent accidents.

On one hand, European gate motor manufacturers use EN 60335-1, which addresses the potential risks and dangers of crushing, shearing, conveying, collisions, lifting and malfunctions of safety devices. The manufacturer can consider additional standards (e.g. EN 60204-1 or EN 60335-2-103) to address the safety of external electrical equipment used with automatic gates such as photocells, control stations, flashing lights, wiring, sensitive edges, etc. - to ensure all automation accessories are safely integrated.

On the other hand, the installation and calibration of the automatic gate motor at the client property must be conducted by competent and qualified personnel. In Europe, this is according to the standards EN 12453 (defining force limits generated by the moving gate) and EN 12445 (test methods to determine the forces). The installer therefore plays a key role ensuring the system is safely installed and it functions in line with the manufacturer’s manuals and the standards.

In the USA and Canada, the standard in use is UL 325 and ASTM F2200 for construction and installation of automatic gates. In general, UL 325 addresses similar risks of electric shocks, fire, mechanical injury and entrapment (e.g. crushing) as a result of using the system. An interesting provision of UL 325 7th edition requires that a sliding gate shall not exceed a speed of 1 ft/sec (~0.30 m/s) for residential properties when the motor is pulling at over 75 lbs (~334 N), with the aim of ensuring the safety of users and their vehicles. Another requirement is to have a minimum of two entrapment (i.e. collision) protection features at all times such as inbuilt auto-reverse function and use of photocells.

In summary, gate motors that adhere to these safety standards significantly reduce the risk of accidents and injuries. Comunello integrates these high standards into their products, and at TropiGuard, we have undergone specialized training at Comunello to ensure expert installation of these systems.

b) Obstacles detection with Photocells

Photocells are safety devices designed to stop the gate from closing if they detect an obstacle like a car or person. When an obstacle is detected, the photocells immediately send a signal to the gate motor to take action, e.g. to stop or reverse the gate motion. These features are particularly essential when children or pets are present in the vicinity of the moving gate. In Europe, these accessories are mandatory to be installed to comply with safety regulations.

Here is how they work: a pair of photocells are positioned directly across from each other, one acting as the transmitter and the other as the receiver. The transmitter sends an infrared signal to the receiver. If something interrupts this signal, such as a person or object, the gate immediately stops moving to avoid accidents.

Photocells are typically placed about 50 cm off the ground to effectively detect obstacles. The alignment must be precise for the system to work, ensuring the transmitter and receiver are perfectly in line. Only the transmitter needs to be connected to the motor control unit and both devices typically require electrical connection to function, although at TropiGuard, we can also supply Comunello photocells that work on batteries.

To keep the photocells working properly, regular maintenance is necessary. Dirt, leaves, or plant growth can block the signal and so, cleaning the photocells is an easy fix in many cases. However physical damage can affect their performance and therefore checking them regularly is important.

c) Encoders

An actuator which integrates a physical encoder can be referred to as an ‘intelligent’ motor. The encoder is a device which consists of a magnet attached to the motor. As the motor rotates, the magnet passes by a pick-up board (also known as a Hall Effect Sensor) which records each pass - effectively allowing the control panel to calculate the number of motor rotations required for a complete gate opening or closing. This information is further processed which eventually allows the control panel to accurately track the gate's position, speed and direction in real-time.

Using an encoder therefore helps the system to detect any abnormal motion or obstacles, stopping or reversing the gate when necessary to ensure safety. This precise feedback from the encoder helps prevent accidents and ensures smooth and efficient operation of the automatic gate. A secondary feature of the encoder is to reduce the energy consumption of the gate motor when in use - as the gate movement does not rely on time of operation to complete its movement, but on the gate exact position.

Note however, some manufacturers quote the use of a ‘virtual encoder’ in their products. A control system with a virtual encoder or no encoder, is simply a motor that lacks a physical encoder. If a virtual encoder is quoted, this means the logic board tracks the cycle as a function of time when the gate is in motion. In this setup, slowdown and approach points are triggered based on the percentage of the cycle time completed. For example, if a slowdown point is set for the last 20% of the cycle, it will consistently activate at that point regardless of other variables that may affect the actual position of the gate leaf.

Because an encoder is such an important device, we are happy to report that almost all Comunello products comes with a physical encoder. Your safety is ensured with us!

d) Other programmable safety features

As it is possible to program the gate motor via its control unit, the following features can be activated for safety and convenience. Look out for these features when you are purchasing your gate motor:

Slowdown on opening and closing (or soft start and stop): these nowadays are standard in most automatic gate systems. Not only does it help to reduce impact forces on the final stages of a gate’s motion, but it also reduces risks of injuries if a person or animal is present

Anti-crush or anti-squash: as the name suggest, the system automatically limits the forces that the gate motor can apply

Auto-reverse: this is a smart feature that commands the gate to stop and reverse if an obstacle is suddenly detected. In the UL 325 standard, it is a feature to be included in the motor whereby it must begin auto-reverse within 2 seconds after an obstacle is detected

Emergency stop: a dedicated emergency stop in the form of a physical switch, or, on the remote control can be added or programmed

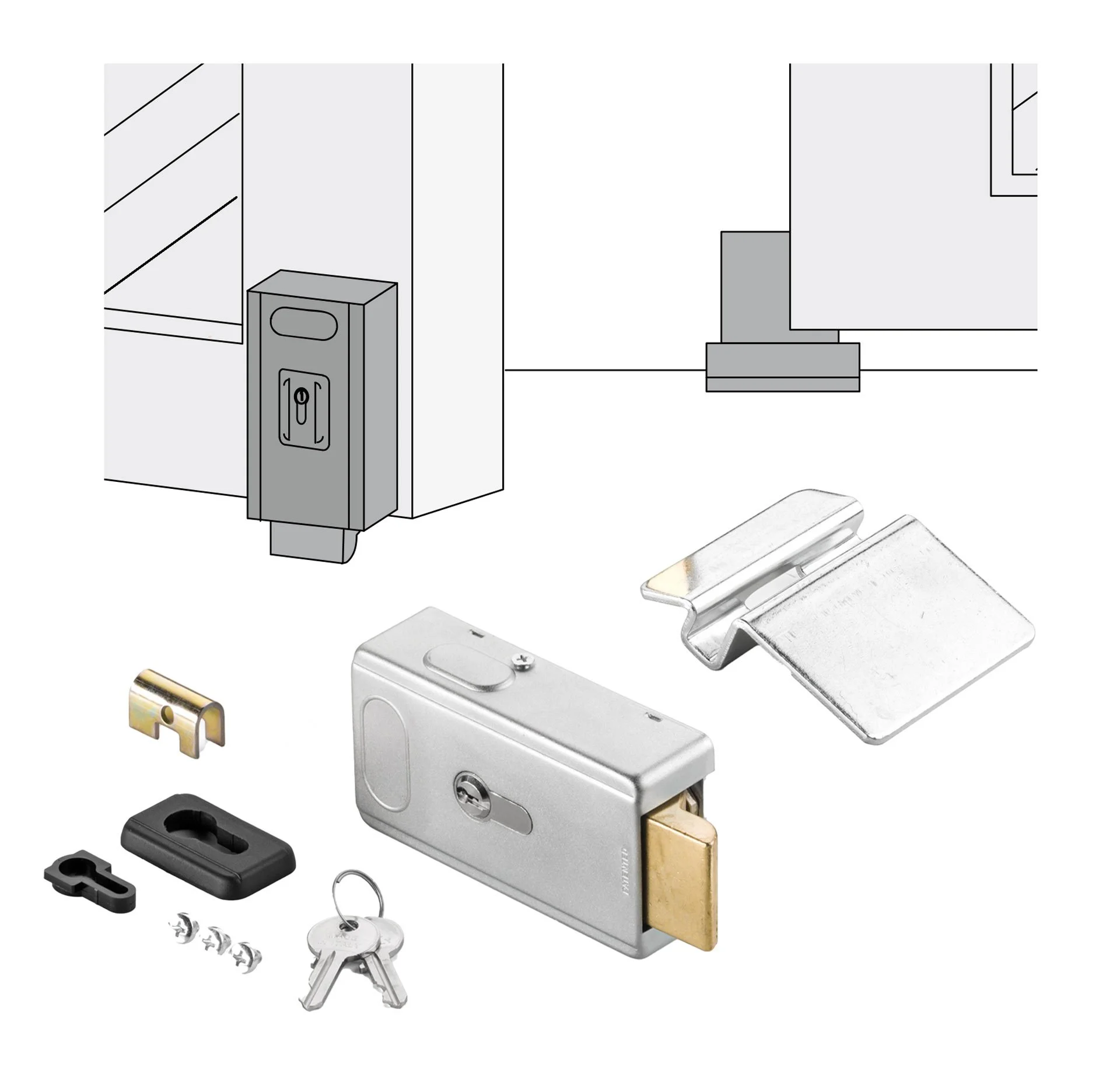

e) Electric locks

This is an optional security feature which you can add to prevent unwanted forced entry by unauthorized users or thieves. It is of course possible to use a manual lock (for example, during night time), but you will need to physically release the lock each time you want to open the gate - which can be an inconvenience.

However, an electric lock integrates with your automatic gate motor, allowing you to unlock the gate via the remote control making it more convenient. Electric locks therefore offer greater ease of access while manual locks are a good budget-friendly option that would require some effort to use. Both types effectively improve security.

Note, Comunello gate motors are engineered to resist substantial force ensuring the gate remains securely closed during attempts to force it open. On sliding gates in particular, it will not be necessary to install an electric or manual lock.

Another security feature that you can consider, is to use remote controls with ‘rolling codes’ instead of ‘fixed code’. The former transmit different encrypted signals to prevent signal cloning by hackers or thieves.

6) Conclusion

Choosing the right motor for your automatic gate does not have to be difficult. By considering the right parameters and features as discussed above, you can find a gate motor that meets your needs. And because Comunello makes great gate motors that excel in each features above, we would recommend you to consider them for your property.

One final tip: regular maintenance is also important to keep your gate motor working smoothly for many years which also saves you time and money in the long run. Depending on frequency of use, regular maintenance of the gate motor is recommended every 6 or 12 months, to keep all components clean and well-lubricated. Watch out for our future blog post on maintenance.

If you are not sure which gate motor is best for you, feel free to contact us! See our automation products page here for more details about Comunello top-of-the-range gate motors.